Connect with us on Youtube!

Connect with us on iTunes!

The Luthier’s Cabinet

How To Protect Your Guitars, Improve Your Workflow, And Increase Your Peace Of Mind

Video Podcast Transcript:

Hey, my name is Tom Bills and I want to welcome you to this edition of The Art of Lutherie Podcast. Today I’m really excited to tell you some stories and share with you some really important lessons that I’ve learned and solutions that I’ve discovered to improve the workflow in my guitar shop, to help better protect my guitars during the construction process as they go through the different phases and also maybe most importantly how to improve just increase my own piece of mind both in the guitar shop and out. So, let me just start by telling you a little back story of a little of my history and kind of like the speed bumps that I hit along the road. Some are speed bumps, some were like total train wrecks. But, some of the things that lead up to what we’re talking about today, when I started which is coming up to almost twenty years, I think next year will be my twentieth year which is hard to believe it went by that fast. Over a hundred guitars, so needless to say that I’ve made a few mistakes and have a couple of crazy freak accidents and weird things happen in the guitar shop and things like that.

But, you know if you approach things the right way, those things you can use them to help you grow and improve and whatever you do don’t let them stop you or make you quit. That’s really important, but, that’s a whole other podcast I think we should do in the future anyway because that’s something I’m passionate about and something really important and critical for guitar makers and any human being I guess right? But, way back when, when I was starting I was building, I think I was still doing smaller batches like three, I think I did some batches of six guitars. But, I’ve always kind of had a tendency to lean towards one at a time building or at least the way I do it now which is each guitar sort of in its own piece of the process of the build and workflow and they’re staggered. So, they are kind of one at a time but they are staggered so one is getting a finish applied, the other one is getting prep for finish and then another one is still being assembled. So, I’m staggering the flow and it keeps me fresh, it keeps me focused. The mass production model was more efficient but, just doesn’t have the passion. It’s just not as much fun and when you pull the fun out and turn it into an efficient job, then what’s the point, right? Because if you’re just in it for a job there might be some other jobs you want to choose over guitar making after making tons of money things like that are being super-efficient.

For me it’s about The Art of Lutherie, it’s about being inspired everyday and trying to do my best work. So, when I was starting and when I did those larger batches I would have a lot of guitars in my guitar shop. You know, I wanted some more stage. I think the very first thing I did, I still have a pipe or a pool that goes across near the ceiling up here and what I used to do is put a hook in the tuner hole of the head stock and I would have the guitars hanging and when the guitars were hanging there of course there is always a danger that something can happen to those guitars during this process and some things did. There was a time when shellac got dumped over and splattered on a bunch of guitars and messed some things up. There was a time when routing some binding and a big chunk of wood shot off and smacked into a guitar. Things like that, just the, even though I never had any total catastrophes happen just the fact that there is guitars hanging there unprotected, sitting out in the open was always in the back of my mind and was always kind of stealing some peace from me and I’m always afraid to move and it felt restricted and confined and after I made, the second thing I did actually is I build this here.

This was my second attempt at finding a place to keep some guitars. I came up with this one after my honeymoon. My wife was nice enough on our honeymoon in Maui, she let me take a day and I drove up and spent a day with Steve Grimes who is a great Lutherie Maui. He had these around his shop filled with guitars you know in different stages and things like that, that was so cool so I was inspired. I came back and I built that. Well after I built this I was excited about my new cabinet and I put some I think it was cocobolo this is way back, don’t tell my wife I forgot what year that was but it was a while ago, fourteen or fifteen years ago and anyway I put some cocobolo or whatever, I think there’s some Indian rosewood, some cocobolo, some backs that I had just braced up and I set them up there in my nice new cabinet. I was going to build the bodies and have the bodies sitting up there. Well, just a couple days before that I cut a hole in the heating duct because it’s really cold in St. Louis. St. Louis has got the worst of all weather. It’s ultra hot in the summer with super hot humidity and it’s you know below zero temperature Fahrenheit of course in the winter and super bone dry. So, the regulating of humidity is always you know something that I’m mindful of all the time. Back then, I kind of didn’t understand it as much as I probably should have and so without thinking I cut a notch to put a vent in so some heat can come in. The next day I come back down and the heat, the super dry heat spraying out of that vent right unto all my wood there are all night long and it split the backs and work things and it was not good. So, that was a little wake up call there that I never forgot. So, then I went through some other things like I have an open shelf over here where that was where I kept everything for a while. No matter what I did there was always a danger of having my guitar while we’re in the process of or while I was in the process of building. Having those guitars out during the building process was always making me nervous and so much so that eventually I got to the point where I was always worried even when I wasn’t in the guitar shop I would you know my workshop to my house.

So, in the night time laying down to go to sleep and I hear a sound and I think oh no, did the guitar fall, did something happen? You know, do I need to go check it? And these thoughts were always in my head. So, anyway, after a while I realized this is not good and I need to find a way to protect the guitars to organize my shop at the same time to protect them from things like wood chips flying, tools being dropped, finish being splattered and drastic humidity shifts and things like that and so I decided that what I was going to do is build something and I’m calling now, I didn’t have a name for it then but, I’m calling it luthier cabinet and that’s this guy right here. This is my luthier cabinet and this simple super simple it looks really, really simple but there is a lot of thought that went into this and a lot of planning that went into this to make sure that it was going to meet the criteria that I needed to improve my life, my workflow and all that stuff and also to protect the guitars and make sure that there wouldn’t be any negative effects of me storing my guitars in here during the building process or my guitar parts or whatever.

Now, integrate into the workflow and help me get more organized at the same time and so that’s kind of the steps that led me up to that. So, it did do just that actually, it actually had a far deeper, far more reaching impact into my work flow and my peace of mind. My shop is always clean no matter. I have four guitars in here now which maybe I’ll cut two and show you what’s going on in there. There’s four guitars being worked on but my shop is clean and everything just flows through there is a workflow that’s built around that and it’s just been a really great thing. I’m not worried. It’s not in the back of my mind that if I drop something it’s going to hurt a guitar and it’s just an amazing thing. So, I highly encourage you that if you have a small space like this and if you’ve been dealing with some of those feelings like worried that a guitar is going to get wreck or if you had some of those freak accidents it might be worth investing a little bit of time into building a cabinet this. If you do decide to do them, if you see the value in this I thought maybe I can save you some time and share some of these main criteria. Just a little bit of the main points that went to designing one of these things that works. I’ve narrowed it down to three main points. One is airflow, the other is workflow and the other is peace of mind. I want to accomplish all three of these things in this design. I want to keep it as simple as possible of course you know as artist and lutherie we’re not trying to build the most complicated system as possible. What we are trying to refine and build the most elegant system as possible. So, when you look at this you think oh that’s just a little cabinet. Essentially it is, but, it has those subtle details that makes it do its job really well.

So, first thing is airflow. So, the thing about airflow I mentioned a little before when the dry area was blasting on those guitars it created, it shocked that wood and it dried that wood out too fast which caused it to split and work and we don’t want to do that. There’s a lot of situations where guitars that are out in the guitar shop can be exposed to a drastic temperature shift. For me one of the challenges I used to have is back in a long time ago I used to spray nitro and every time I would spray, I had a spray booth over in the other part of my shop and I would turn on that fan and I would have to pull in air from outside and as you know now I live in St. Louis, Missouri. So, within the middle of winter I’m pulling in air with a relative humidity of ten per cent. Maybe even four per cent if it’s snowy outside or something and then in the summer I’m pulling in air that’s relative humidity of eighty per cent. So, there were some drastic shifts in the relative humidity that can shock the wood and cause problems. Unless the wood is protected somehow. On the other side of the coin, if I were to build a draw like this or a cabinet and I would seal that guitar in there then that guitar would be overly separated from this environment and could cause problems because maybe the humidity shifted out here. Let’s say one part of the guitar, the neck is over here and the body is in here, if the body is at one humidity and the next at another and I get it out and glue it together, we’re going to have problems. We want to find the balance of the airflow so that, in the simplest possible most elegant way there is airflow through the cabinet enough to keep things at a equilibrium, equal state so there is relative humidity in the cabinet and out here is the same. But, we want to regulate the airflow enough so if there is a sudden shock to the whole place it’s going to be a buffer and it’s and going to slow down that transition. So, that the guitars in here aren’t going to get shocked. That’s number one. That’s kind of built into this design here.

The second thing is my workflow. So, what happened was rather than just having three drawers here to just throw stuff in, it’s divided into a nice system. The bottom drawer is where I keep the guitars at earlier stages. So, essentially when a guitar is first being built, the sides are bent and things like that before that happens they are going to on my shelf here and it’s okay because I’m a little less concerned the parts aren’t really glued together so they can expand and contract and they’re not affecting one another. But, once I get the sides bent, I join the tops and backs. In this case, these are large tops and start carving them, they are going in here. But, what’s really cool is that all the parts of the guitars are in here. So, it organizes it for me. I’ve got the binding is bent for one of these in here. I’ve had the necks, the finger boards, the brace wood, I’ve already got all this stuff together and ready to go and it’s all organized in here so I know exactly what part goes with what guitar and that’s really important for me because each guitar that I build is very different and so I have to keep straight which piece of per-fling or whatever which builds guitar. This makes it very easy because it all goes in here. Once I move a little further into the assembly of it then it’s going to graduate up to draw number two. Draw number two has guitars typically that are being prepped to go into the finishing stage and again it’s nice because the whole guitar fits in here even with the neck glued on and everything is organized like the pick-up is in here all the ebony for all the tail piece and this is another arch top, the tail piece and bridge and everything is all in here too.

I know exactly what goes with what guitar all that stuff so that’s in here to keep it safe as I’m working. Then once it’s ready to go into the finishing stage I’m ready to go up here to the top draw and this is where I keep my guitar while I’m doing my French polishing. Each day after I do French polishing for me I like to do it first thing in the morning. So, I wake up in the morning, I do my session of French polishing and it goes back in the drawer and stays safe and sound but still has the airflow to help it cure properly and of course I’ve got a few things in here like the material for the nut and saddle just to keep things organized. I do keep a little hygrometer inside one of the draws as well just to monitor it and always make sure everything is in as I am assuming and thinking that it is. So, that’s how it goes for the workflow. Then, of course obviously after the finish is done I keep it in here to set up, put the strings on, comes out of here goes into the case and goes off to it’s new home. The next guitar graduates up, a new fresh set of sides being bent and another sort of kit if you want to call it that I put together, the neck and all those stuff that I have for that guitar that I’ve chosen for that design or whatever. Then, that goes down at the bottom and the cycle continues and meanwhile when I’m working when I’m in the shop or when I’m not here I have the third important thing which is peace of mind. I know that the guitar is safe and if I’m getting ready to go to sleep in the night, I know that I don’t really care because whatever it was it didn’t hurt any of my guitars cause they are safe in my luthier cabinet.

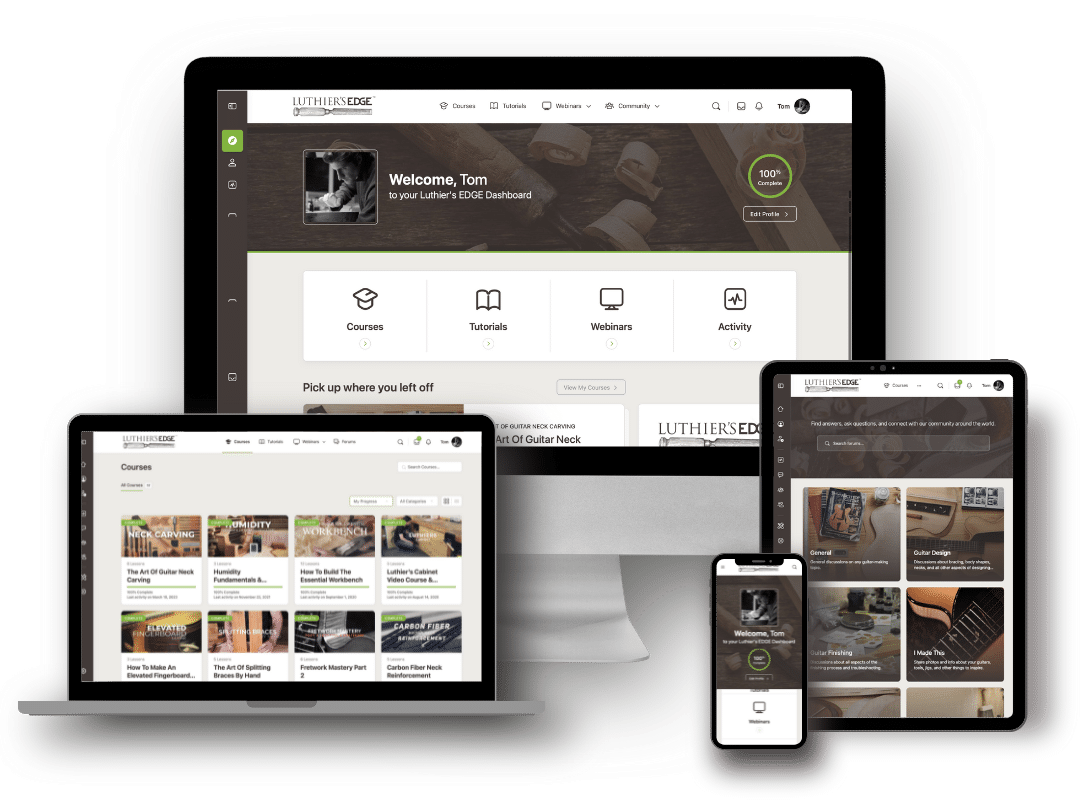

So, hopefully that gave you some inspiration and some ideas and you may want to build your own luthier cabinet and kind of think about your workflow maybe and how you can incorporate that and improve that and maybe save yourself a little bit of worrying about if your guitars are okay as you’re sitting on your benches and stuff. If you’re a member of the Luthier’s EDGE, I have a full detailed blue print and a micro course of all the different steps that built this cabinet, the measurements, the materials and you know each of the videos in the micro course I walk through talk about the way it’s designed why it’s designed the way it is. Really, the why behind it. Everything we do on the Luthier’s EDGE is about helping you understand “why” you know, so the Luthier’s EDGE is really designed to be something that’s a supplement to whatever else you’re doing. If you’re building a guitar from a book, the Luthier’s Edge is going to have support and materials and training and stuff. And a community of builders too, to help you go deeper and not just be flowing steps but understanding “why”. So, if you are a member of the Luthier’s EDGE and you’re watching this you can login right now and download these blue prints for the luthier’s cabinet and you can take the micro course on it. If you’re not a member then you can pop over to the art of lutherie dot com and learn more about the Luthier’s EDGE and see if maybe you want to become a member too. So, that’s it for this podcast. I hope you enjoyed it and I will see you next time thanks.