In this article, I’ll answer the most common questions about carbon fiber guitar neck reinforcement and share the key concepts you’ll need to effectively use carbon fiber rods to improve the strength and stability of your guitar necks.

Here are the main topics we’ll cover today:

- What is Carbon Fiber

- The Carbon Fiber Type I Use

- Carbon Fiber Guitar Neck Design

- Optimal Carbon Fiber Bar Placement

- The Neck Layout And Measurements I Use

- Carbon Fiber And The Elevated Fingerboard

Sound good? Let’s dive in…

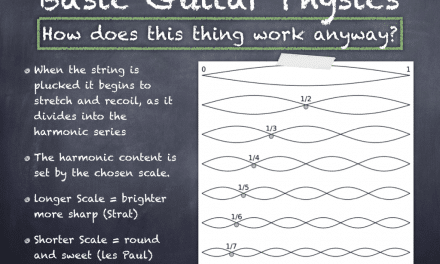

What is Carbon Fiber?

The use of carbon fiber guitar neck reinforcement has been growing in popularity over the years, and for good reason. Carbon fiber exhibits some wonderful qualities that lend themselves to the making of fine handmade instruments and can offer the luthier some great options for adding strength and stability without unwanted mass.

Some of these great qualities include light-weight, great stiffness, resistance to creep, and stability.

Carbon fiber (or graphite fiber) consists of carbon atoms combined together in crystals parallel to the long axis. Several thousand carbon fibers are combined to form a “Tow” which can be woven into a fabric or used in other ways. The crystalline structure, aligned along the long axis, gives the material incredible strength for its weight.

To me, it sounds crystalline when you touch it and is very resonant, which I think has to do with the organized structure of the crystals, but that’s just my hunch. I have also been fascinated by the electrical and heat conduction properties that carbon fiber possesses as well, but that’s for another day.

History Of Carbon Fiber

When I am using any material, I like to know a little bit about it, how it’s made, which we discussed above, and also some background.

I feel it helps me to improve my intuitive understanding of it, which comes in handy to guide me as I’m working with it and experimenting with different ways to incorporate it into my designs.

So here’s just a bit of background that I found interesting.

Thomas Edison, According to Wikipedia, it seems that none other than Thomas Edison made some of the first carbon fiber when he invented the light bulb. He superheated cotton thread and bamboo slivers to produce carbonized fibers for his filaments used in some of the first light bulb experiments in 1879. (Thomas Edison is shown in the photo to the right with a carbon filament light bulb)

It wasn’t until the 1960s though, that the process and technology were able to create the material pure enough to take advantage of the amazing high strength-to-weight ratio of carbon fiber.

Rolls-Royce was one of the first companies to begin using it for their propeller blades. From there, the material was further refined and went on to be used in many specialized and amazing applications, such as fine musical instruments.

Get step-by-step instructions on this topic; check out the

Carbon Fiber Guitar Neck Reinforcement Video Course

Carbon Fiber Applications For Guitars

There are many different uses for carbon fiber in guitar design, ranging from simply laminating into tone bars, neck reinforcements, creating a full exoskeleton around the outside of the guitar, making the entire guitar from carbon fiber, and countless other applications.

Above are a couple of examples; on the left is a really cool application of carbon fiber neck exoskeleton by Jeff Traugott , and on the right is a full carbon fiber guitar by Rainsong. (Click the images for more info on those guitars. )

In this article, however, we will be focusing on how to strengthen and stabilize the guitar neck using carbon fiber bars or rods as shown in the image below:

The type I use is the .200 X .240 carbon fiber bars from StewMac which are perfect for my guitar necks. I especially like that they are pre-cut to the lengths I need, as cutting this material can hard on your tools. And I can just buy one set if that’s all I need at the time.

I also use a router bit designed for inlaying those rods. It’s inexpensive, doesn’t burn the wood in the channel while cutting, and it’s convenient to order it from the same source as the rods.

Guitar Neck Design With Carbon Fiber Bars

When considering the best layout for your guitar neck, there are a few important factors that come into play:

- Neck wood

- Neck profile

- String tension

- Neck thickness

With those parameters in mind, we can start thinking about how to position the carbon fiber in the neck for the best results.

Carbon Fiber Placement

Below are a few photos that show some different carbon fiber-reinforced neck layouts to consider.

Remember that a taller bar adds more strength per unit of weight than a wider bar. That’s one reason I use a layout similar to example #2 above. I find this layout to add strength and stability to the neck, and I use it for all of my steel string and archtop guitars.

I highly recommend making some full-scale neck cross-section drawings of your own to be sure you will not hit those bars as you carve your neck profile. (I discuss this in my Truss Rod Guide as well.)

Always take the time to double-check and make sure your design is solid and your measurements and calculations are correct on paper first.

Neck Layout And Measurements I Use

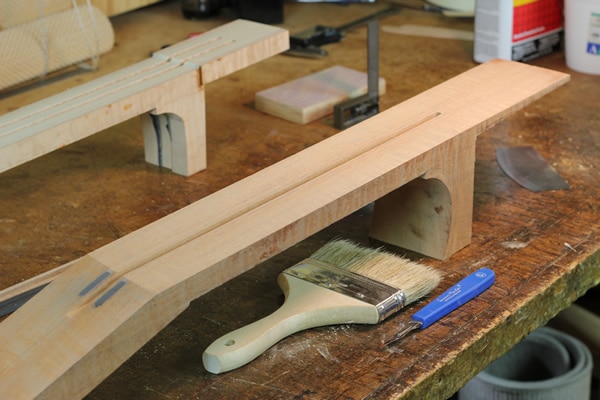

First, I route my truss rod slot in the center of the neck.

Then, I route my channels for the carbon fiber rods into the neck blank, leaving ⅛” of neck wood on either side of the truss rod channel. I route them at a depth of .020″ deeper than the height of the carbon fiber bars.

In my case, the bars I use measure .25″ tall, so my channels are cut to a depth of .27″.

Lastly, I add wood veneers over the CF bars (See the photo below)

Inlaying the carbon fiber bars a little deeper into the neck results in a little more stiffness, too.

Elevated Fingerboard & Neck Extension

One other aspect of designing your carbon fiber reinforced guitar neck is considering the portion of the fingerboard that extends out over the body of the guitar.

I like to use an elevated fingerboard design for archtops, steel strings, and nylon string guitars. It helps the fingerboard remain stable and have the proper shape for optimum setup and playability.

*Learn more about the benefits of the elevated fingerboard design here.

The elevated fingerboard also provides an excellent way to extend the carbon fiber out over the body of the guitar for stability, evenness of tone, and neck relief all the way to the end of the fingerboard.

So, there you go!

I hope this email has answered your questions and has given you a great starting place for using carbon fiber to ensure that your guitar necks are strong, stable, and play great when new and for many years to come.

If you want to go deeper, there are more advanced tricks and techniques to properly installing the carbon fiber bars that just couldn’t fit here into this article,

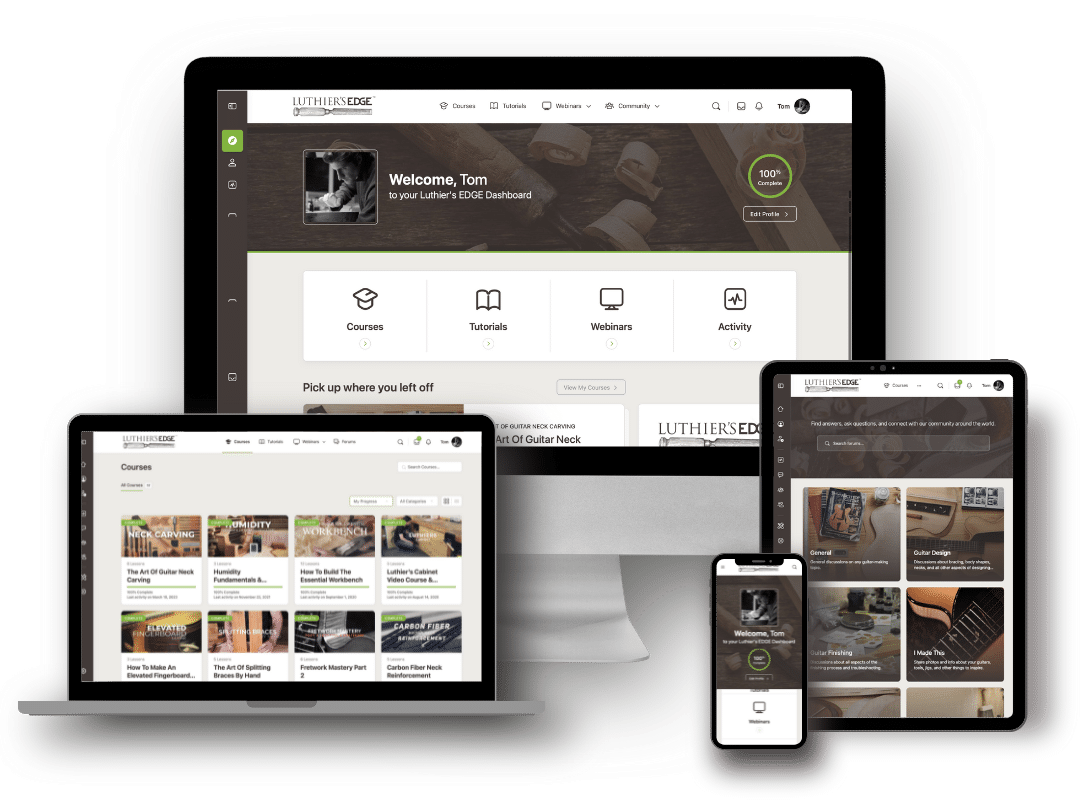

My entire process is included and demonstrated in the Luthier’s EDGE course: